Wireless electronic Crankshaft deflection device

Our patented technology delivers

Wireless (know-how) solution with a 3m data transfer range, making data retrieval.

Ergonomic, easy to use - easy to read sensor data even on the opposite side of the open crankcase door.

Utilises the same industrial mini-computer (iPC) as the engine pressure indicator ELPI.

Engine performance takes less than one minute per cylinder.

Unique (know-how) TDC finding method. It allows to calculate mean indicated pressure Pi power Ni without sensor on the flywheel.

Compact - Weight with sensor 450g - Case size 32 x 26 x 7 cm

Workflow

Watch our video demonstration to see just how quick and easy it is to analyse crankshaft deflections using EDD.

How it works

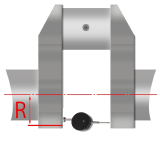

Fit the EDD sensor between crankshaft web

Collect wireless data on mini-computer (iPC)

Connect the iPC to PC via USB cable.

Import data from a iPC.

Time Savings

The EDD eliminates all of the time consuming and awkward tasks involved with mechanical micrometer dials.

Simple

Due to its simplicity and durability, the deflection indicator can be used frequently for deflection checks.

Economy

The EDD helps users to identify potential problems even before they arise and then require expensive engine repairs.

Technical Data

Measuring range (distance between crankshaft webs)

100 - 800 mm

Accuracy

0.01 mm or 0.001 mm depending on requirements

Wireless range

3 m

Power

Rechargeable battery

Weight with sensor

450 gr